- Continuum Mechanics studies the deformation and transmission of forces through a continuous material.

Stress and Strain

-

Stress pertains to a force that causes a deformation on an object.

-

Strain pertains to the deformation that results from strain.

-

Hooke’s Law states a relationship between the stress

and the strain is given by Where

is the elastic modulus. - The elastic modulus depends on the material the object is made of.

-

In general, the stress

experienced across a surface can have any direction relative to

Uniaxial Stress

- Let

be a force applied perpendicular to the cross sectional area. When tension is acting on the object, then the tensile stress calculated as When compression is acting on the object, then the compressive stress can be calculated instead. It is the same calculation above exceptchanges sign. - This assumes that stress is evenly distributed over the entire cross section

- If the object has length

with cross sectional area and has no defects, Saint-Venant’s principle states that the stress can be assumed uniformly distributed over the cross sectional area over any cross section that is more than a few times from both ends.

- The tensile / compressive strain is defined by taking the change in length into account

- Young’s Modulus is given as the elasticity modulus for tensile and compressive forces

Bulk Stress

-

Bulk Stress acts on an object experiencing equal compression or tension in all directions and always directed perpendicularly to the surface independent of the surface’s orientation.

If all the forces involved are compression forces, then the bulk stress is simply the pressure

. -

The Bulk Strain is defined by

-

The Bulk Modulus for compression / pressure is defined as

- We include the negative sign to reflect the fact that increases in pressure mean a decrease in volume.

- For small pressure changes in a solid or liquid,

is constant. - The Bulk Modulus of a gas depends on the initial pressure

-

The compressibility is defined as the reciprocal of the Bulk Modulus

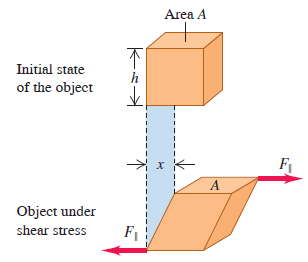

Shear Stress

-

Shear stress occurs when a uniformly thick layer is attached to two stiff bodies that are pulled in opposite directions in parallel directions. It is defined as

- Any plane perpendicular to the layer will have a net internal force and stress of

. - Shear stress only applies to solid objects which have a definite shape.

- Any plane perpendicular to the layer will have a net internal force and stress of

-

The shear strain is defined as the ratio of the displacement

to the distance between the two surfaces . -

The Shear Modulus is defined as

When Hooke’s Law Doesn’t Apply

-

Hooke’s Law is not true in general. It assumes the material is sufficiently elastic.

-

There is a proportional limit such that beyond this point, Hooke’s Law is no longer obeyed.

-

The yield point of an object is the point such that increasing the stress beyond this point causes an irreversible deformation on the object.

- Before the yield point is reached, the material is still elastic — any deformation can be reversed by removing the stress

- This is not necessarily true if the material has been stretched multiple times. In this case, the material experiences elastic hysteresis where, due to friction, the work needed for the material to return the object to its original length is less than the work required to deform it.

- After the yield point is reached, the material is plastic — any deformation due to stress cannot be reversed even if the stress is removed

- The elastic limit is the stress at the yield point.

- Before the yield point is reached, the material is still elastic — any deformation can be reversed by removing the stress

-

The fracture point is the point when a small stress causes a large strain to the point that the object breaks entirely.

- The material’s breaking stress is the amount of stress required to actually fracture the material.

-

A material is brittle if it breaks soon after reaching its elastic limit.

-

A material is ductile if it can be given a large permanent stretch without breaking